FAVO S-TLIF

3D printed cages of the new generation

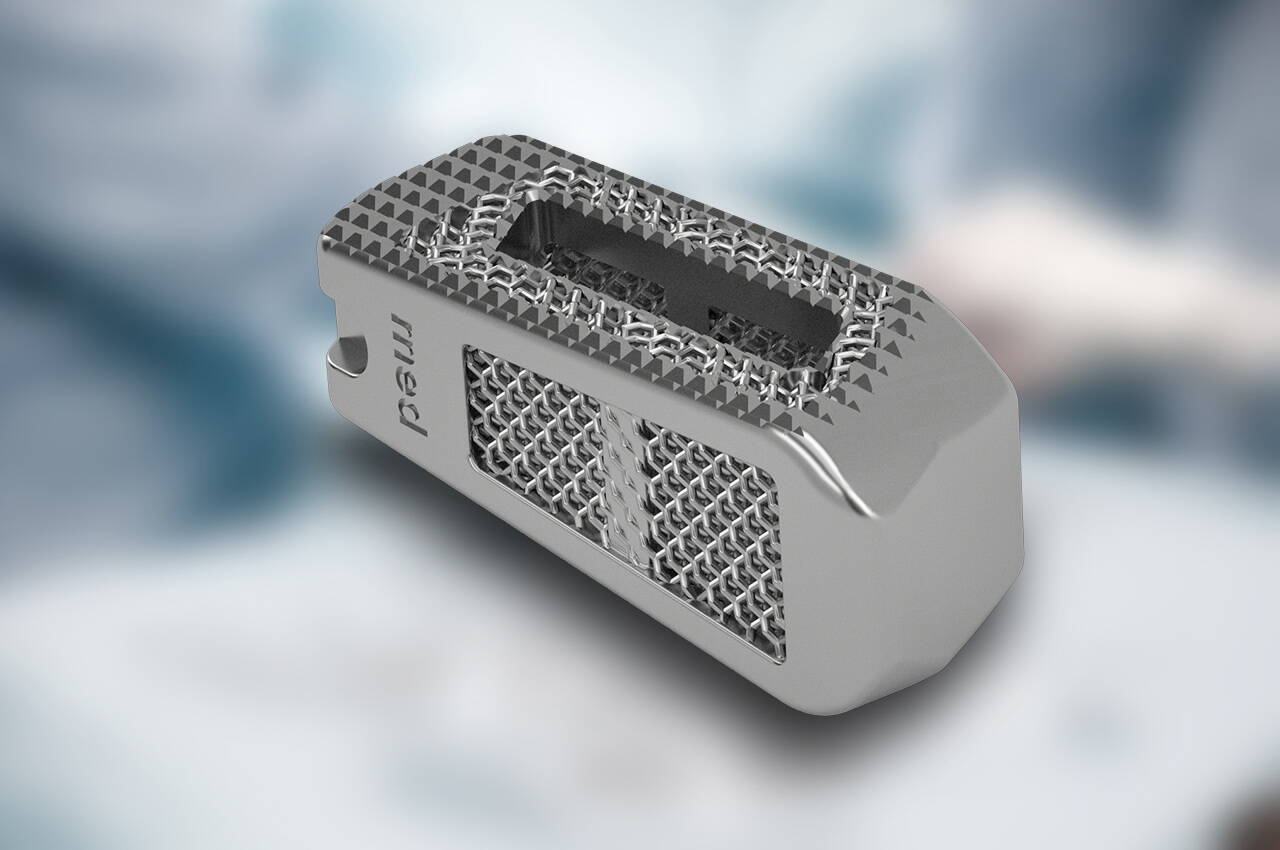

The latest manufacturing technology, 3D titanium printing, enables an open-porous cage design with a mesh structure consisting of approximately 73% air and 27% titanium. The porosity and pore size of the cage are similar to cancellous bone, which promotes bony integration. The open-porous structure of the cages also ensures clear visibility of the implants, largely without disturbing artifacts.

Specially designed for oblique insertion

The cage has an oblique lordosis angle. The offset bullet nose supports oblique insertion and positioning. The fenestration for bone material also helps to identify the final cage position.

Manufacturer:

| FAVO S-TLIF | Width | Hight | Length | Lordotic Angle |

|---|---|---|---|---|

| 11 mm | 7-13 mm (1 mm increment) | 28 mm | 5° | |

| 11 mm | 8 - 13 mm (1 mm increment) 15 mm | 33 mm | 5° | |

| 11 mm | 9 - 13 mm (1 mm increment) 15, 17 mm | 38 mm | 5° | |

| 11 mm | 9 - 13 mm (1 mm increment) | 28 mm | 10° | |

| 11 mm | 10 - 13 mm (1 mm increment) 15 mm | 33 mm | 10° | |

| 11 mm | 11 - 13 mm ( 1 mm increment) 15, 17 mm | 38 mm | 10° | |

| 11 mm | 11 - 13 mm (1 mm increment) | 28 mm | 15° | |

| 11 mm | 12, 13, 15 mm | 33 mm | 15° | |

| 11 mm | 13, 15, 17 mm | 38 mm | 15° |